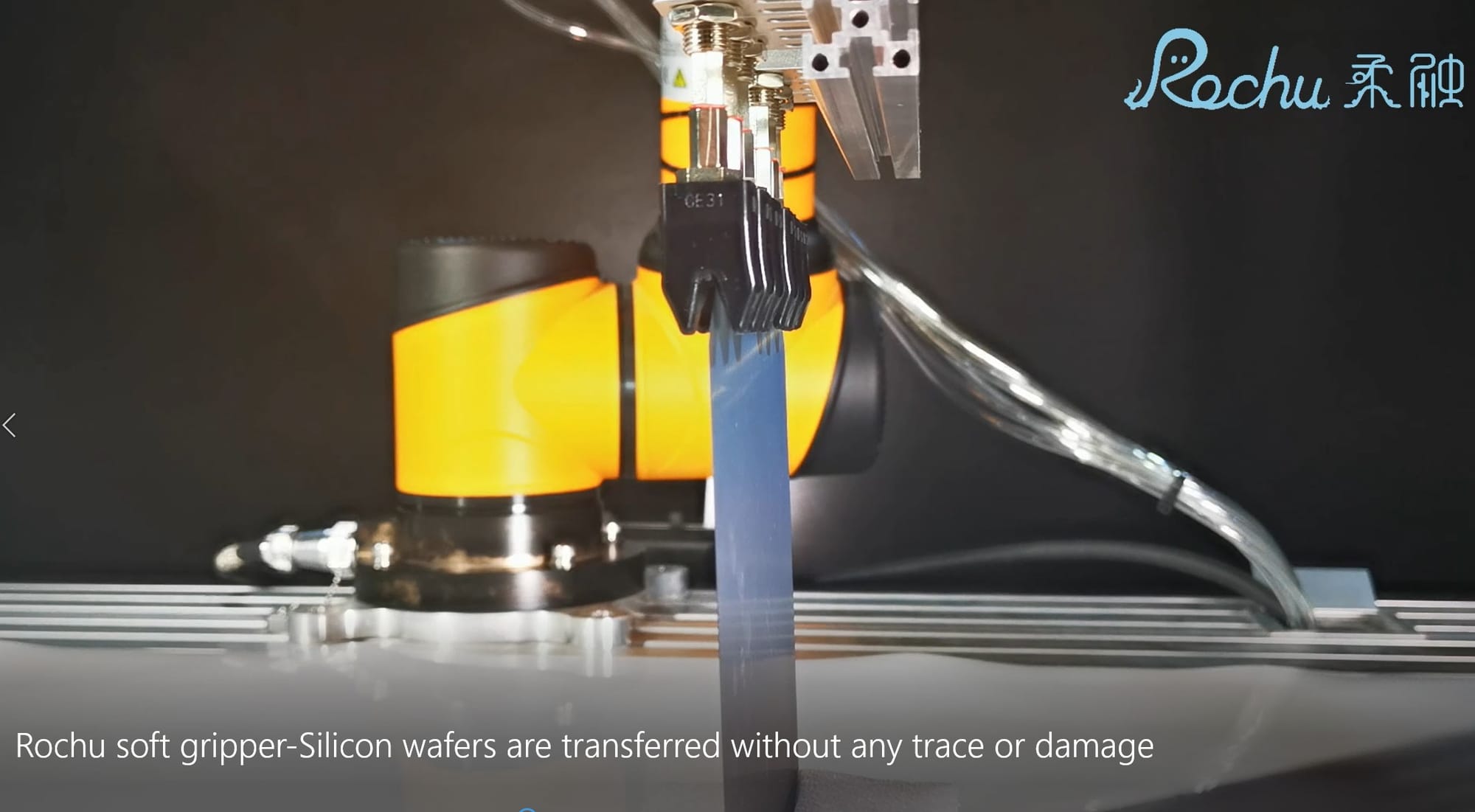

Rochu soft gripper-Silicon wafers are transferred without any trace or damage

The 0.2mm thick silicon wafer is not only brittle and fragile, but also more susceptible to environmental influences such as residues, oil stains, dust and sweat on fingers during manual cleaning, polishing and sorting. Moreover, tools such as vacuum gripper will leave traces of the shape which are not easy to be erased. It takes much labor and time, seriously affecting the appearance of products. The conventional rigid gripper is easy to cause edge breakage, hidden crack, and reduce the yield. So how can wafers like silicon be moved seamlessly by a robotic hand?

https://www.youtube.com/watch?v=X5AVZ3j2XIU

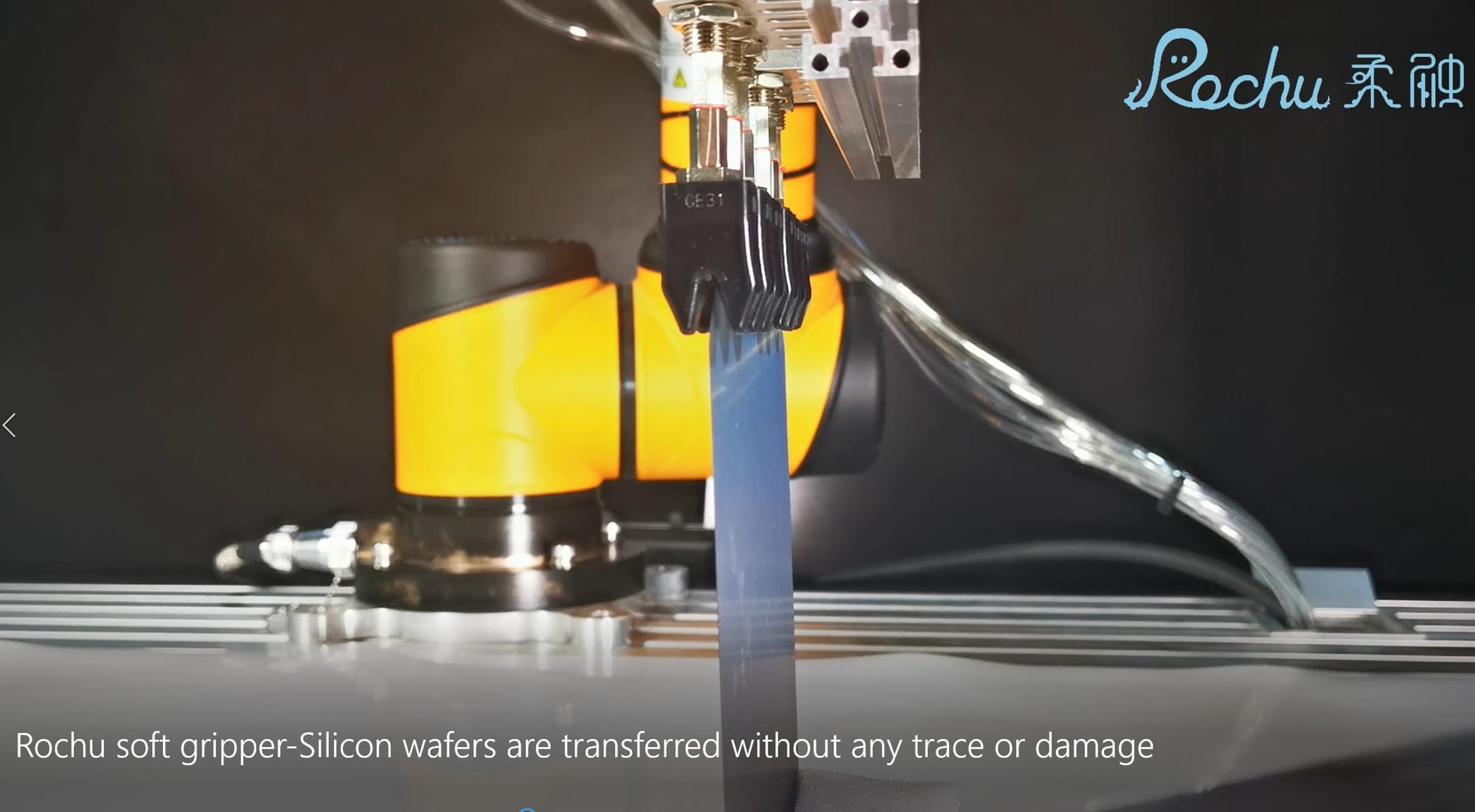

Except for silicon wafer, glass panel, PCB board automatic production line upgrade will also face the same problem.Fortunately,Rochu flexible anti-static fingers do not produce dust and do not touch dust, avoid sensitive surfaces, pinch edges and grasp, easily carry silicon wafers without any trace and damage, ensure the surface of products without defects, improve the rate of good quality.

(Picture: transfer 0.3mm thick glass sheet with Rochu anti-static and no trace fingers)

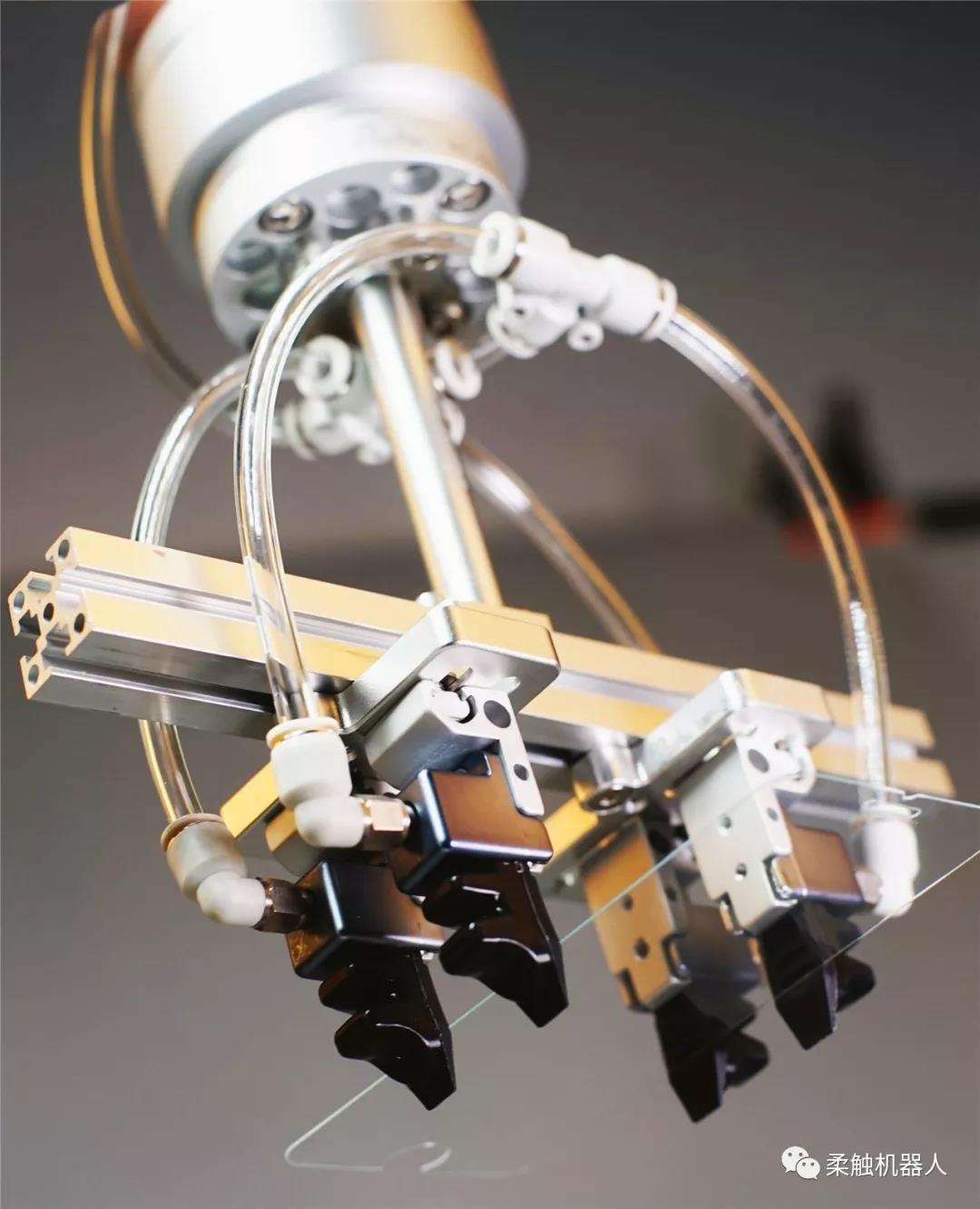

Plastic, glass and other materials are very good electrical materials, these two kinds of non-conductive objects after friction, contact will produce a lot of static electricity.Moreover,Rochu soft fingers not only have soft trackless characteristics,but also could effectively prevent the generation of static electricity.

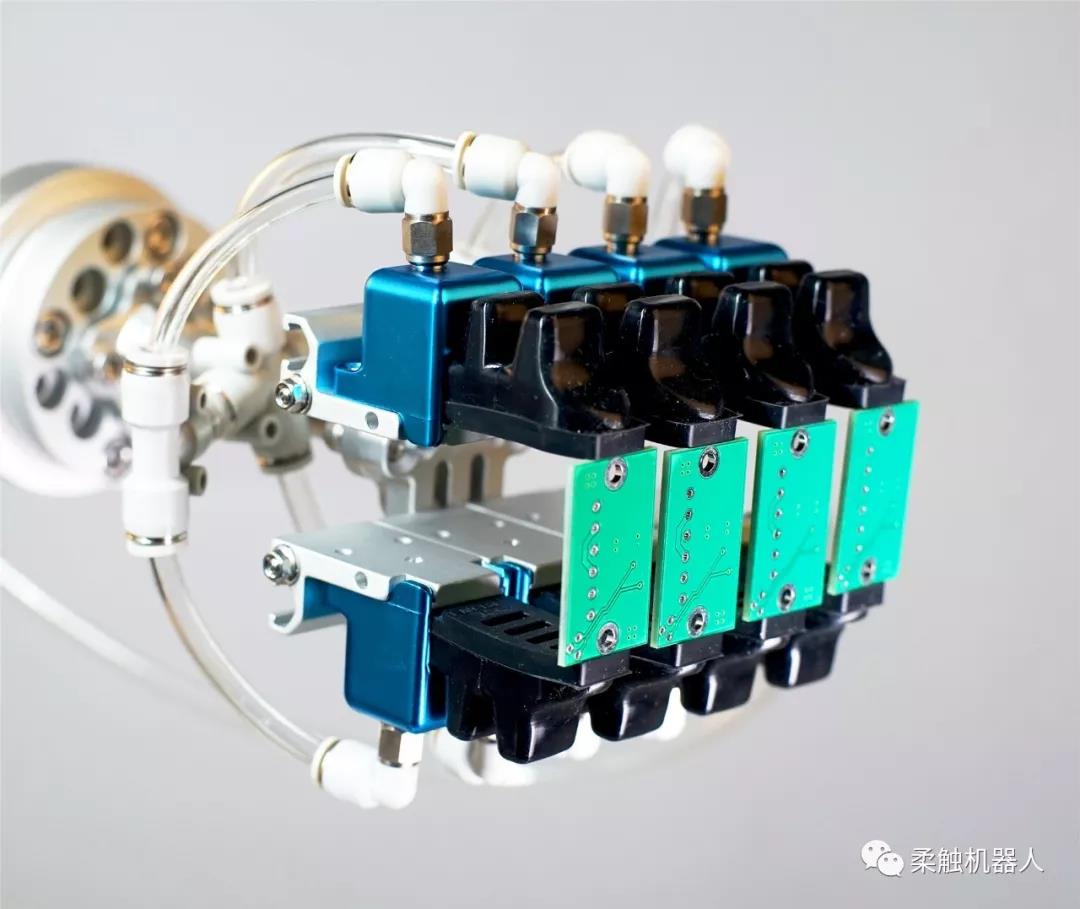

(Picture : shows PCB board handling of the Rochu flexibleanti-static finger module)

Since then, Rochu group is not only the manufacturer of soft robotic gripper, but also the expert of comprehensive flexible gripper solution.Nowadays, the anti-static and no-trace fingers can be applied in the automatic production to ensure the integrity and blemishes of sensitive components, and enable the mechanical arm to expand its application in 3C electronics, semiconductor, photovoltaic and other industries.